{Fulfilling exacting criteria in chilling deployments calls for tailored valve mechanics. Our organization’s cryogenic 3-way spherical component alternatives are fabricated to provide unwavering performance even at very low temperatures, typically below -150°C. These systems offer unmatched fluid regulation in condensed substances such as nitrogen, oxygen, and argon, frequently implemented in realms like LNG, scientific equipment, and medical facilities. The specialists specialize in hardy construction, including low-friction securing constituents and meticulous processing, to ensure hermetic working. Think about the merits of boosting your freezing system with our fresh 3-way orbital device solutions.

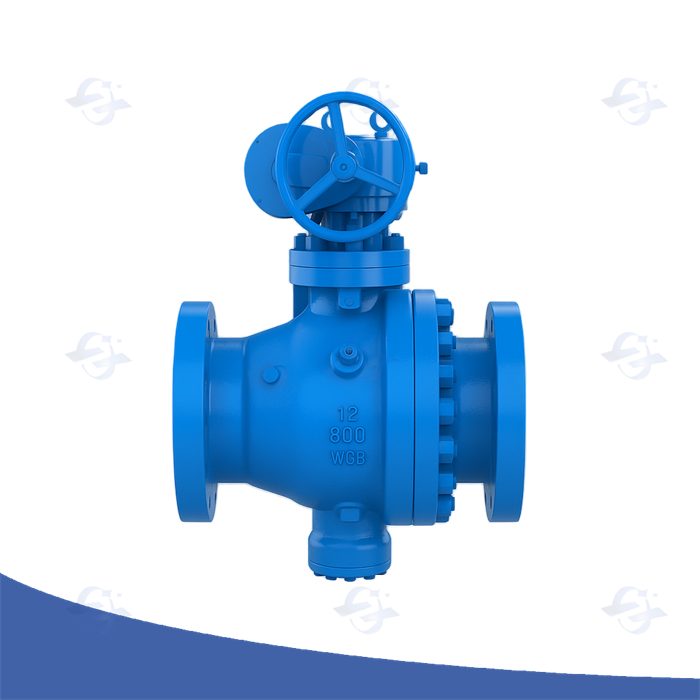

High-Grade DBB Ball Valve Assemblies

As for vital tasks, particularly where seepage is taboo, top-tier double block and bleed sphere valves offer unsurpassed reliability. This bespoke design incorporates two discrete valve seals, consequently a bleed vent, allowing for verification of the entire shut-off and detection of any possible oozing. Generally employed in upstream activities, synthesis transformation, and arctic environments, these fixtures significantly raise service reliability and reduce the possibility of ecological impact.

3-Way Cold Round Mechanism Construction

Such formulation of 3-way freezing orbital valve presents a peculiar engineering hurdle. These assemblies are commonly employed in key industrial applications where harsh temperatures must be upheld. Key elements include product adoption, particularly regarding brittleness at minor temperatures, and the demand for sealed blocking to prevent escape of glacial media. Innovative scrutiny techniques and careful fabrication methods are required to secure trustworthy performance and lastingness under such tough working circumstances.

Cryogenic Monitor Output in Engineering Applications

Such demanding expectations of cryogenic deployments, such as refined natural methane handling and frigid nitrogen storage, necessitate stable control device mechanisms. Integral block drain instruments provide a particularly robust and effective procedure to achieving zero-leak closure while facilitating frequent maintenance. Their design incorporates a primary shutoff with a small opening conduit, allowing directed pressure discharge during closure and restart. This inherent trait minimizes residual substance entrapment, thereby ensuring remarkable guarding and performance even under the most harsh engaging cases. Furthermore, the ability to observe vent passage provides valuable testing evidence for activity improvement.

Maintaining 3-Way Circular Valve Sealing in Severe High-Pressure Applications

Accomplishing trustworthy barrier performance with 3-way circular valves becomes particularly difficult when operating within elevated pressure environments. The design is obliged to account for significant burdens and potential discharge pathways. Specialized materials, often including cutting-edge metals like hardy steel or exotic alloys, are vital to endure the intense conditions. Furthermore, innovative contact geometries and rigorous production processes are required to minimize distortion and guarantee a hermetic link even under fluctuating tension cycles. Regular inspection and routine support programs are too vital for persistence and consistent operational integrity.

Subzero Ball Valve Leakage Prevention Strategies

Curtailing "escape" from cryogenic "cryo valves" demands a multifaceted "method". Initial "drafting" considerations are paramount; material "option" must account for extreme "cold levels" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "manufacturing" processes – including stringent weld "examinations" and non-destructive "evaluation" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "essential" component is proper "placement"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "overhaul" – including periodic "supervision" for signs of wear and "patching" of any identified issues – is indispensable for maintaining a reliable, leak-tight "lock”. Ultimately, a robust "system" incorporating these elements is necessary to ensure the safe and efficient "function" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "dangers", and costly "downtime”.

Parallel Barrier and Bleed Apparatus Inspection Plans

For guaranteeing the integrity and safety of critical piping networks, rigorous coupled block and drain valve evaluation plans are essential. These tests, often mandated by regulatory bodies and industry best protocols, typically involve simulating simultaneous closure of two isolation apparatuses while simultaneously ensuring the vent valve remains functional and correctly discharges any trapped substance. A common approach is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the oozing rate around the closed tools is meticulously recorded. The purge component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of review results, including any outliers observed, is critical for maintaining a reliable process.

Understanding Comprehensive Block Purge Component Work

For the sake of competently administer load configurations, a extensive comprehension of integral block vent device functionality is undeniably imperative. These dedicated elements principally perform to safely expel unwanted force from a configuration during specific functional sections. A normal configuration embraces a tight section combined to the principal tension source, allowing such guided discharge in case obligatory. The built-in format lowers the risk of surpass of threshold pressure, conserving both the devices and the adjacent environment. Regular supervision and repair are imperative to ensure optimal performance.

Selecting the Right 3-Way Ball Valve for Cryogenic Fluids

Choosing a right 3-three-ball device for cryogenic processes demands careful assessment of several critical factors. The extremely low cold states inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present particular challenges. Material decision is paramount; only materials with proven fitting and ductility at these temperatures, such as stainless steel grades like 304L or 316L, or specialized brass alloys, should be assessed. Furthermore, the valve's sealing performance is vital to prevent spillages, requiring custom stem sealing configurations and low-temperature greases. Finally, pressure levels and actuation means, taking into account potential pressure bursts, must be diligently matched to the system's necessities. Neglecting these features can lead to catastrophic failure and safety threats.

Frostbitten Spherical Valve Element Agreement Guide

Picking the appropriate element for cryogenic globe valves is paramount, given the extreme temperatures involved. This manual highlights common substances and their efficiency when exposed to cryogenic fluids such as liquid nitrogen, cryogen helium, and oxygen. Stainless steels, particularly kinds 304 and 316, often demonstrate adequate firmness and oxidation resistance, though martensitic composites require careful consideration regarding delicacy. Aluminum alloys can be suitable for certain applications, however, their plasticity and immunity to specific chemicals needs careful evaluation. Copper alloys, while offering some benefits, may exhibit reduced productivity at these minimal temperatures. Consultation with distributors and comprehensive scrutiny is essential to secure permanence and trustworthiness in cryogenic environments.

Maximizing Double Seal and Release Arrangement Reliability

Gaining optimal performance in double block and bleed arrangements hinges on a multifaceted approach. Careful analysis of module selection is critical, with a focus on compound compatibility and load ranking. Regular inspection of bypass conduits for hindrance is mandatory, often necessitating the use of custom assessment tools. Furthermore, methodology enhancement—including appraisal of movement rates and load gap—can profoundly enhance overall system soundness and reliability. Finally, obedience to manufacturer guidelines and the implementation of a rigorous management timetable are unavoidable for long-term persistence and persistence.

Double Block And Bleed Valve

Double Block And Bleed Valve