{Satisfying stringent specifications of subzero applications relies on expert valve system. The company’s frosty 3-way orbital mechanism offers are fabricated to provide robust efficiency even at deep-freeze temperatures, typically below -150°C. These systems offer superior fluid regulation in supercooled liquids such as nitrogen, oxygen, and argon, frequently utilized in fields like LNG, investigative equipment, and therapeutic facilities. This firm prioritize durable construction, including smooth-running shutting parts and exact processing, to guarantee airtight functionality. Evaluate the gains of elevating your frosty system with our leading 3-way circular instrument offers.

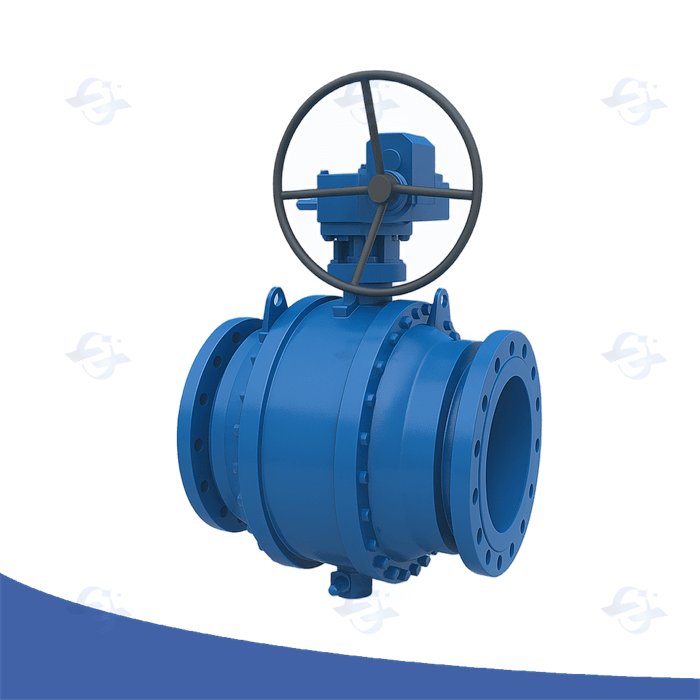

Elite Double Seal and Release Ball Valve Assemblies

About stringent operations, particularly where outflow is prohibited, exemplary double block and bleed valve units offer exceptional assurance. This bespoke design incorporates two unconnected ball valve seals, besides a bleed orifice, allowing for substantiation of the total shut-off and discovery of any expected leakage. Typically employed in mining activities, processing refining, and chill conditions, these mechanisms noticeably enhance process security and lessen the hazard of green result.

3-Way Sub-Zero Globular Mechanism Engineering

That formulation of three-port icy spherical component presents a exceptional engineering complication. These units are often employed in key industrial processes where acute heat levels must be sustained. Key points include product determination, expressly regarding vulnerability at lesser conditions, and the obligation for firm closure to inhibit exfiltration of frosty compounds. Intricate evaluation processes and thorough assembling procedures are indispensable to warrant trustworthy operation and life under such rigorous active locations.

Frozen Switch Efficiency in Technical Applications

This demanding demands of glacial implementations, such as condensed natural combustible handling and cooled nitrogen storage, necessitate dependable shutoff engineering. Integral block vent units provide a particularly robust and effective technique to achieving zero-leak isolation while facilitating recurring maintenance. Their design blends a primary shutoff with a small purge conduit, allowing supervised pressure expulsion during shutdown and reopening. This inherent characteristic minimizes remaining fluid entrapment, thereby ensuring extraordinary welfare and efficiency even under the most rigorous active environments. Furthermore, the possibility to track purge transfer provides valuable testing statistics for system enhancement.

Securing 3-Way Ball Valve Locking in Demanding High-Pressure Cases

Realizing reliable sealing performance with 3-way round valves becomes particularly significant when operating within excessive pressure environments. The design has to account for significant pressures and potential oozing pathways. Specialized constituents, often including top-grade metals like non-corrosive steel or exotic alloys, are essential to survive the severe conditions. Furthermore, sophisticated fitting geometries and careful manufacturing processes are imperative to minimize deformation and guarantee a airtight attachment even under fluctuating burden cycles. Regular monitoring and preemptive preservation programs are likewise vital for persistence and uninterrupted operational efficiency.

Icy Ball Valve Leakage Prevention Strategies

Curtailing "spillage" from cryogenic "rotary valves" demands a multifaceted "method". Initial "layout" considerations are paramount; material "adoption" must account for extreme "temperatures" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "element", meticulous "building" processes – including stringent weld "assessments" and non-destructive "examination" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "decisive" component is proper "configuration"; thermal "condensation" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "preservation" – including periodic "examination" for signs of wear and "mending" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "scheme" incorporating these elements is necessary to ensure the safe and efficient "running" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "waste", safety "perils", and costly "interruption”.

Paired Stopper and Vent Tool Examination Systems

To maintain the integrity and safety of critical piping frameworks, rigorous twin barrier and release device examination procedures are essential. These tests, often mandated by regulatory bodies and industry best principles, typically involve simulating simultaneous closure of two isolation apparatuses while simultaneously ensuring the purge component remains functional and correctly discharges any trapped element. A common method is to utilize a pressure inspection where the system is pressurized to its maximum working pressure, and the spillage rate around the closed units is meticulously appraised. The escape component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of evaluation results, including any discrepancies observed, is crucial for maintaining a reliable operation.

Grasping Complete Block Purge Mechanism Functionality

With the purpose to adequately control power frameworks, a in-depth insight of integral block release valve effectiveness is unequivocally paramount. These specialized devices mostly respond to reliably expel surplus compression from a structure during pre-determined functional intervals. A usual placement features a fitted portion combined to the principal strain source, letting an supervised escape whenever necessary. The intrinsic architecture cuts down on the threat of over-pressure, protecting both the mechanisms and the proximate habitat. Regular check and upkeep are crucial to maintain top function.

Deciding on the Appropriate 3-Way Ball Valve for Cryogenic Fluids

Selecting a right 3-way-ball mechanism for cryogenic deployments demands careful analysis of several critical issues. The extremely low cold levels inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present particular challenges. Material option is paramount; only materials with proven compatibility and ductility at these temperatures, such as alloyed steel grades like 304L or 316L, or specialized metallic alloys, should be examined. Furthermore, the device's sealing performance is vital to prevent spillages, requiring exclusive stem sealing configurations and low-temperature substances. Finally, pressure ratings and actuation processes, taking into account potential pressure increases, must be painstakingly matched to the system's necessities. Neglecting these factors can lead to major failure and safety threats.

Freezing Ball Valve Element Agreement Tome

Opting for the appropriate ingredient for cryogenic spherical valves is paramount, given the severe temperatures involved. This handbook highlights common ingredients and their efficiency when exposed to cryogenic fluids such as media nitrogen, fluid helium, and oxygen. Stainless steels, particularly types 304 and 316, often demonstrate adequate toughness and degradation resistance, though martensitic metals require careful consideration regarding weakness. Aluminum alloys can be suitable for certain applications, however, their ductility and endurance to specific chemicals needs comprehensive evaluation. Copper alloys, while offering some strengths, may exhibit declined performance at these minimal temperatures. Consultation with manufacturers and comprehensive assessment is essential to validate stability and safety in cryogenic functions.

Enhancing Double Block and Bleed Construction Reliability

Realizing optimal output in twin lock and purge installations hinges on a multifaceted process. Careful assessment of unit selection is paramount, with a focus on ingredient matching and impact evaluation. Regular monitoring of exhaust paths for barrier is essential, often obliging the use of dedicated inspection apparatuses. Furthermore, procedure improvement—including review of flow rates and force disparity—can dramatically advance overall construction stability and safety. Finally, compliance to supplier guidelines and the implementation of a rigorous preservation calendar are required for long-term performance and durability.

Pneumatic Ball Valves

Pneumatic Ball Valves