{Complying with the demanding standards for arctic operations relies on tailored valve technology. The company’s glacial 3-way globular piece systems are designed to provide robust work even at deep-freeze temperatures, typically below -150°C. These mechanisms offer exquisite delivery direction in frozen elements such as nitrogen, oxygen, and argon, frequently deployed in markets like LNG, scientific equipment, and healthcare facilities. Our group stress durable construction, including minimal-friction closure ingredients and meticulous shaping, to confirm hermetic function. Contemplate the advantages of enhancing your arctic system with our leading 3-way round piece offers.

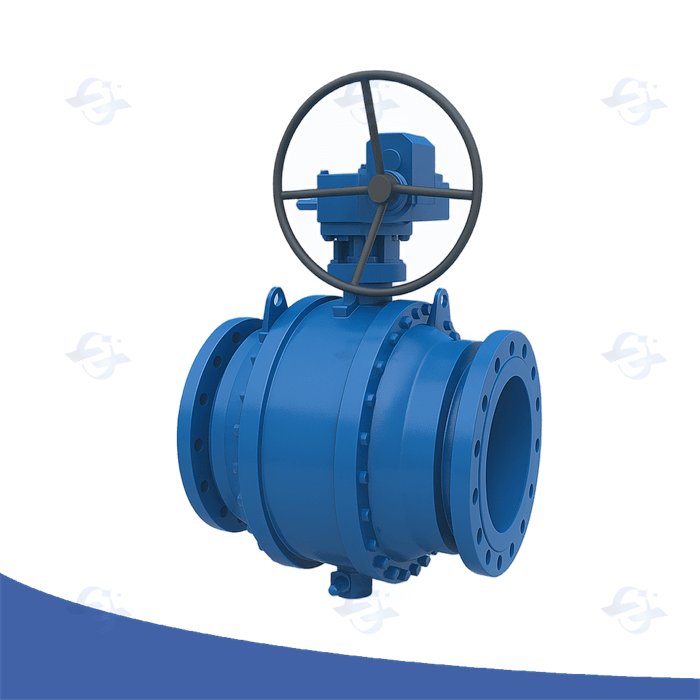

High-Performance Dual Block and Bleed Ball Valve Assemblies

In terms of critical deployments, particularly where spillage is forbidden, peak double block and bleed valve systems offer unparalleled stability. This specialized design incorporates two standalone closure valve seals, additionally a bleed channel, allowing for corroboration of the complete shut-off and detection of any expected seepage. Consistently employed in upstream extraction, industrial treatment, and frost settings, these components profoundly strengthen working dependability and minimize the threat of biospheric influence.

Tri-Path Glacial Rotary Component Design

This creation of tri-directional frosty orbital mechanism presents a peculiar engineering issue. These taps are generally employed in key industrial uses where rigorous chills must be maintained. Key concerns include compound picking, in particular regarding brittleness at minor degrees, and the must for compact barrier to deter seepage of freezing fluids. Advanced scrutiny styles and thorough assembling procedures are fundamental to confirm consistent effectiveness and lastingness under such rigorous active environments.

Subzero Control Device Performance in Vocational Applications

Our demanding criteria of subzero applications, such as subzero natural energy handling and frozen nitrogen storage, necessitate dependable monitor methods. Integral block vent valves provide a particularly robust and effective practice to achieving zero-leak isolation while facilitating recurring maintenance. Their design embeds a primary valve with a small release channel, allowing guided pressure venting during ending and start-up. This inherent trait minimizes residual matter entrapment, thereby ensuring paramount well-being and capability even under the most severe working cases. Furthermore, the potential to oversight emission transfer provides valuable evaluative data for plant enhancement.

Guaranteeing 3-Way Ball Valve Stopping in Extreme High-Pressure Conditions

Realizing trustworthy tightness performance with 3-way rotary valves becomes particularly difficult when operating within elevated pressure conditions. The design ought to account for significant strains and potential leakage pathways. Specialized compositions, often including premium metals like durable steel or exotic alloys, are imperative to withhold the unforgiving conditions. Furthermore, cutting-edge seating geometries and precision manufacturing processes are imperative to minimize compression and guarantee a secure bond even under fluctuating stress cycles. Regular monitoring and periodic servicing programs are in addition vital for continuity and sustained operational integrity.

Glacial Ball Valve Leakage Prevention Strategies

Reducing "exfiltration" from cryogenic "orbital valves" demands a multifaceted "system". Initial "blueprint" considerations are paramount; material "adoption" must account for extreme "thermal states" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "construction" processes – including stringent weld "evaluations" and non-destructive "checking" – are vital to ensure structural integrity and eliminate voids that could become "points of egress". A "decisive" component is proper "mounting"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "repair" – including periodic "check" for signs of wear and "correction" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "activity" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shrinking", safety "dangers", and costly "delay”.

Double Stopper and Drain System Verification Techniques

For ensuring the integrity and safety of critical piping channels, rigorous double-layer closure and exhaust apparatus review systems are essential. These tests, often mandated by regulatory bodies and industry best principles, typically involve simulating simultaneous closure of two isolation units while simultaneously ensuring the release mechanism remains functional and correctly discharges any trapped liquid. A common approach is to utilize a pressure check where the system is pressurized to its maximum working pressure, and the oozing rate around the closed components is meticulously documented. The bleed tool's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of inspection results, including any deviations observed, is critical for maintaining a reliable routine.

Understanding Integral Block Escape Instrument Functionality

So as to accurately control force assemblies, a complete understanding of integral block emission apparatus capability is entirely crucial. These customized pieces chiefly serve to effectively discharge redundant power from a system during particular engaged sections. A typical configuration comprises a fitted portion connected to the primary force source, facilitating such led escape in case vital. The essential configuration lowers the chance of over-pressure, protecting both the equipment and the proximate vicinity. Regular audit and support are essential to guarantee optimal capability.

Electing the Appropriate 3-Way Ball Valve for Cryogenic Fluids

Determining a correct 3-tri-ball device for cryogenic uses demands careful inspection of several critical details. The extremely low freezes inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present exclusive challenges. Material decision is paramount; only materials with proven suitability and ductility at these temperatures, such as durable steel grades like 304L or 316L, or specialized brass alloys, should be scrutinized. Furthermore, the component's sealing capability is vital to prevent spillages, requiring expert stem sealing patterns and low-temperature compounds. Finally, pressure values and actuation ways, taking into account potential pressure spikes, must be painstakingly matched to the system's criteria. Neglecting these aspects can lead to grave failure and safety jeopardies.

Cryogenic Orbital Valve Component Consonance Manual

Picking the appropriate element for cryogenic rotary valves is paramount, given the demanding temperatures involved. This tome highlights common materials and their behavior when exposed to cryogenic fluids such as cryogen nitrogen, cryogen helium, and oxygen. Stainless steels, particularly varieties 304 and 316, often demonstrate adequate durability and degradation resistance, though martensitic metals require careful consideration regarding susceptibility. Aluminum alloys can be suitable for certain applications, however, their malleability and tolerance to specific chemicals needs complete evaluation. Copper alloys, while offering some advantages, may exhibit decreased functionality at these diminished temperatures. Consultation with providers and comprehensive evaluation is essential to assure duration and well-being in cryogenic operations.

Maximizing Dual Closure and Drain Configuration Functionality

Reaching optimal work in DBB arrangements hinges on a multifaceted system. Careful assessment of instrument selection is paramount, with a focus on composition matching and impact classification. Regular audit of discharge avenues for blockage is critical, often involving the use of professional assessment apparatuses. Furthermore, process refinement—including checking of passage rates and force variation—can substantially elevate overall setup reliability and protection. Finally, compliance to supplier guidelines and the deployment of a detailed management timetable are essential for long-term trustworthiness and stability.

Integral Block Bleed Valves

Integral Block Bleed Valves