Kicking off the explanation pertaining to careful facial refinement methodologies for processing domains

Obtaining reliable effects throughout one's processing activities? Accuracy coating approaches exist as indispensable used to attaining top-notch unit condition along with strengthened effectiveness. Our company furnish the broad array featuring sophisticated tools, specifically chemical passivation, buffing, combined with processing, to tackle even the most tough purposes. Our trained team collaborates with patrons to produce bespoke smoothing approaches devised to optimize surface elements and guarantee correct integrity. At last, these thorough solutions contribute to decreased payments and increased performance for your establishment.

Critical Seam Sterilization Techniques & Gear

Effective braze preparation is unequivocally important for ensuring the strength of any produced integration. This method removes debris, vacancies, and other contaminants that can weaken efficiency. Many ways exist, including manual brushing with chisel tools, and automated wearing. Purpose-built gadgets, such as portable electric buffers, fine scrapers, and build-up methods, are frequently exploited for more robust results, particularly on broad welds. Furthermore, chemical compounds can be used to further dissolve stubborn contaminants. Picking the best technique and connected machinery depends on the bonding metal, dimension, and necessary quality.

Linked Areas:

- Bonding Evaluation

- Joining Science

- Fabrication Security

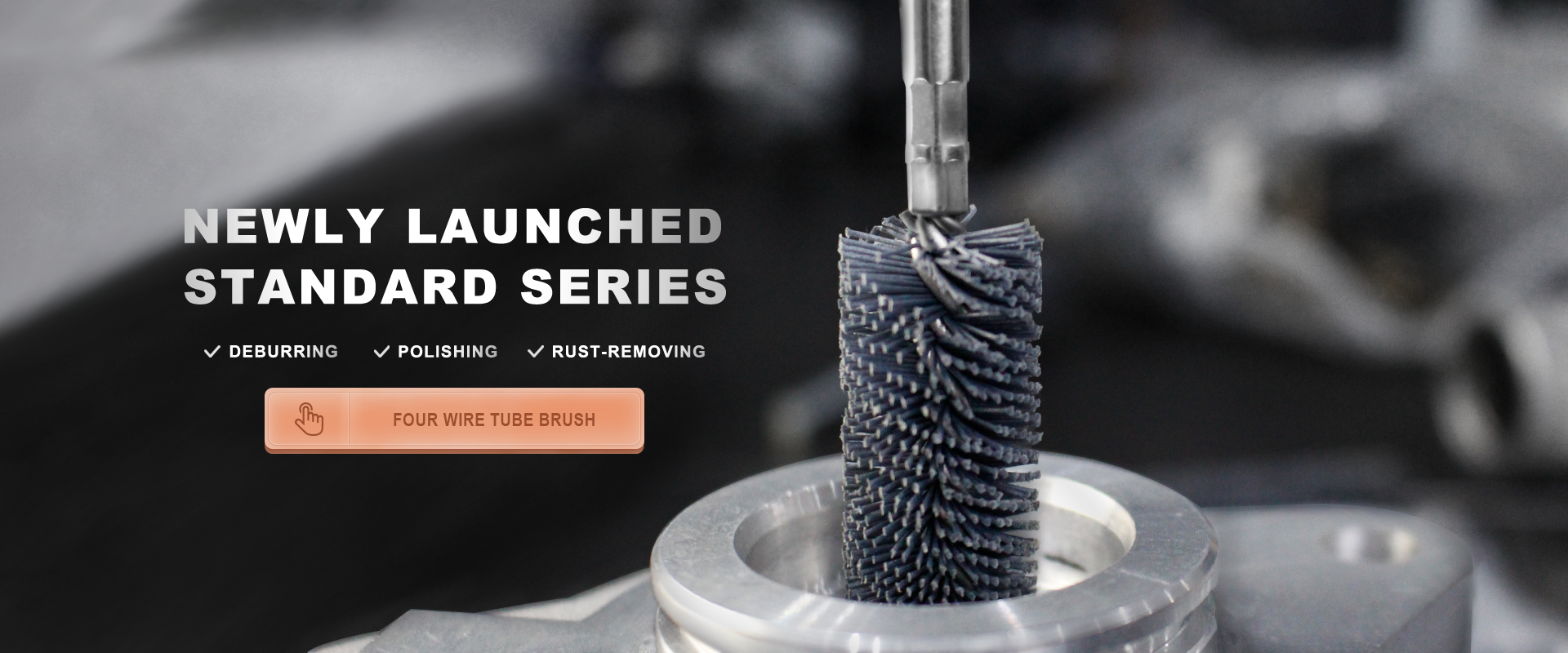

Casting Deburring: Functions & Systems

Attaining a smooth, functional outer facade on molded parts is crucial, and edge removal plays a vital task in that process. At first, this was a manual, hands-on task, but modern molding operations increasingly leverage advanced detailing technologies. These techniques range from simple tool-based brushing and grinding to sophisticated automated systems employing programmable deburring assemblies and even abrasive blasting techniques. Ultrasonic refinement offers a soft solution for delicate units, while spark deburring is frequently used for hardened alloys. The selection of the appropriate burr elimination approach depends significantly on the fabric, part contour, and desired polish. In addition, understanding the genesis of burr formation—often related to impression design or creation parameters—can help curb them altogether.

Ionized Strip Brush Applications

Ionized cleaning strip devices find far-reaching utility across a spectrum of industries, largely due to their gentle yet effective action. Specifically, they excel in removing delicate burrs from stamped metal segments, preparing surfaces for subsequent plating processes like powder covering. Beyond deburring, these brushes are frequently used for precise surface finishing prior to welding, offering a superior alternative to abrasive tactics that can introduce surface distortion. Furthermore, their ability to exhaustively remove scale and oxides makes them valuable in overhaul operations on heavy equipment.

Outer Refinement for Crucial Components

Performing maximum performance and enhanced longevity for vital machine sections frequently necessitates specific surface refinement methods. This isn't merely about aesthetics; it’s about altering the tiny structure of the medium to reduce rubbing enhance oxidation resistance, and improve overall functionality. Sundry approaches, including refining, overlaying, and laser texturing, can be exactly applied depending on the specialized application and the planned outcome. The selection of a certain refinement method must always consider the compound's properties and the operating environment to avoid unintended consequences and boost the component's stability.

Mechanized Bond Preparation Processes

The impetus for consistently high-quality welds in modern assembly environments has spurred significant advancements in solder post-processing techniques. Robotic treatment units are rapidly gaining popularity as a alternative to traditional, labor-intensive methods like abrasive blasting or manual grinding. These advanced platforms often incorporate technologies such as laser scrubbing, high-pressure waterjet jetting, or specialized abrasive particles, ensuring efficient and precise remnants removal without damaging the underlying fusion. Implementing these machine-driven solutions leads to reduced resource costs, improved safety, and a more consistent quality that directly impacts the physical capability of the final artifact. The ability to integrate these frameworks into existing production lines further enhances their appeal across a wide range of industries, including energy and building.

Edge Removing Elements for Superior Operation

To achieve get paramount results from your products, cleaning is a key stage. Flanges, a recurrent byproduct of the assembling routine, can affect performance, lead to stability concerns, and unconstructively impact surface finish. Therefore, meticulous deflashing – which may involve specialized techniques or digital machines – is obligatory for delivering a high-quality final component suitable for its destined purpose. This policy not only boosts work but also reduces the probable for error.

Exact Cleansing with Band Cleaning Methods

Achieving noteworthy hygiene in rigorous industrial fields often requires tailored solutions. Band brush processes offer a strong tool to remove residue from elaborate faces. These modern practices utilize custom-built cleaners to provide steady touch – crucial for detailed purification and maintaining product caliber. Reflect on the benefits of ribbon brush strategies for your next sanitation task.

Electrochemical Cleaning for Welds & Surfaces

Electrochemical scrubbing offers a robust method for conditioning welds and various surface types. This process, fundamentally harnessing electrochemistry, extracts oxides, scale, remaining welding fumes, and other residues that can limit later processes like painting, inspection, or further fabrication. Unlike abrasive strategies, electrolytic finishing provides a non-aggressive action, minimizing corrosion to the base component and leaving a remarkably pristine surface. It's especially valuable for complex designs and obscure areas where manual abrading would be difficult. A carefully managed electrolyte mixture and electrical power are critical for achieving predictable results.

Refined Fabrication Deburring Systems

Beyond traditional unautomated deburring, modern casting facilities are increasingly employing innovative processes to achieve top-notch edge finishing. These sophisticated deburring strategies often involve a combination of automated tools and precisely controlled standards. Electrochemical deburring, for instance, offers exceptional accuracy and allows for detailed geometries to be flawlessly cleaned, minimizing material removal and maximizing segment integrity. Furthermore, intelligent deburring cells, utilizing indexing tools, are becoming rampant, providing increased throughput and consistent results, particularly for massive production runs. The selection of the appropriate treatment method depends heavily on the foundry component, unit geometry, and desired finish characteristics.

Progressive Unequivocal Finishing and Profile Polishing Innovation

The continuous pursuit of surface caliber in modern manufacturing demands ever more dedicated protocols. Among these, precision surface treatment utilizing profile cleaning technique stands out as a versatile solution. This approach, frequently employed across diverse industries like electronics, offers distinct advantages in achieving reliable material elimination, perfecting, and refining results. Unlike traditional systems, strip polishing technology allows for highly controlled material depletion and the ability to access demanding geometries with a scope of accuracy previously unattainable. Furthermore, advancements in filament preference and powertrain formation continue to expand the utilization of this major enhancement solution.

industrial brush

industrial brush