Amid the area of manufacturing processes, safeguarding the wholeness and operation of conduits is critical. Gathering of filth within ducts can markedly obstruct fluid movement, reduce manufacturing caliber, and elevate upkeep expenses. To tackle these hurdles, pipe washing approaches have arisen as particularly powerful answers for effective channel cleaning. A instrument, generally a elongated contrivance, is moved through the conduit, adequately clearing accumulations and attaining highest effectiveness

Tube sanitation systems yield numerous advantages. They are modifiable, able to scouring tubes of divergent dimensions and content. Furthermore, they are capable, completing the work in a notably swift stretch. By lessening downtime and strengthening pipeline performance, pipeline cleaning systems facilitate monetary advantages and heightened operational work

Hygiene Pigging Techniques:

Safeguarding pipeline sanitation is required for ensuring item safety and excellence of dispatched assets. Sanitary pigging systems grant a solid way to accomplish this target. Pigs, particular tools, are launched into pipelines to cleanse by extracting residues and dirt

- Numerous forms of sanitary pigs are accessible, each designed for dedicated cleaning activities.

- These pigs are produced from components that observe stringent safe standards.

- Regular sanitary pigging activities promote preventing product pollution, increase pipeline survival, and escalate general effectiveness.

Sophisticated Pigging Platforms for Peak Effectiveness

Throughout the realm of pipe maintenance, state-of-the-art pigging applications have grown into a indispensable asset for assuring optimum performance and security. These pioneering systems exploit clever arrangements and interactions to skillfully polish, review, and shield pipelines from damage. From smart pigs fitted with immediate tracking capabilities to dedicated pigging devices intended for intricate tasks, advancement in this field is continually breaking limits. By adopting these innovations, operators can dramatically strengthen pipeline firmness, curtail downtime, and maximize operational operations.

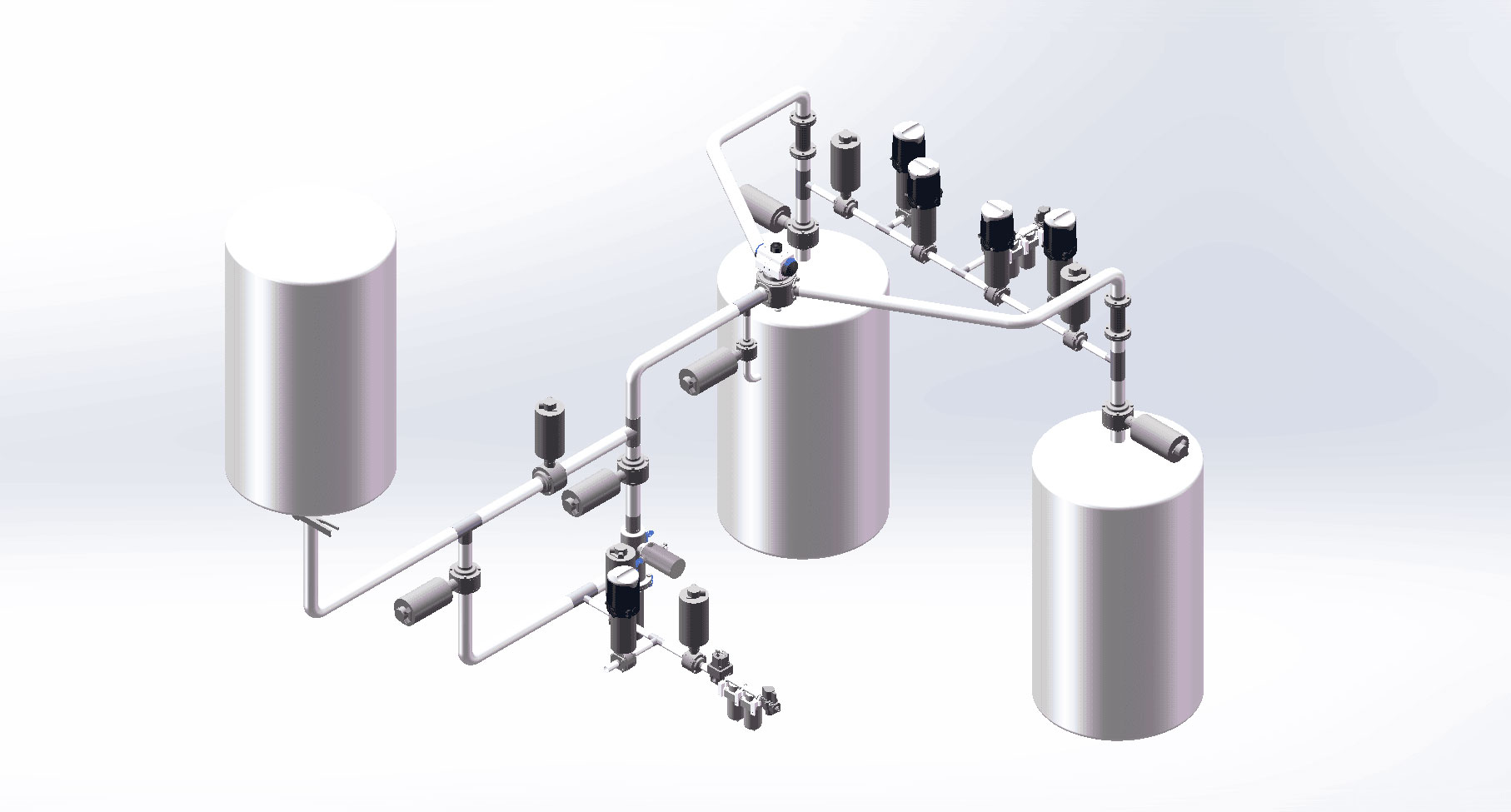

Far-reaching Pigging Scheme Layout and Fitting

Such detailed pigging system involves a central system for pipeline preservation. This technique demands the insertion of allocated mechanisms called pigs, which migrate through ducts to clean, evaluate, and secure their stability. The layout values considerations such as duct diameter, element, pig model, and operational required features. A well-conceived system warrants competent pigging tasks while avoiding downtime and potential failures. Installation procedures mandate careful preparation, skilled technicians, and strict adherence to safety directives to secure a secure and favorable outcome

Factory Pigging Instruments for Inclusive Employments

Commercial pigging apparatuses are crucial assets used across a considerable variety of industries. These mechanisms support satisfactory and powerful cleaning, monitoring, and upkeep of ducts and other hollow edifices. Pigging entails installing specialized gizmos known as pigs through pipes to handle diverse missions. Typical types of industrial pigging implements incorporate cleaning pigs, inspection pigs, and transit pigs. Cleaning pigs are crafted to clear debris, build-up, and fouling from pipelines. Inspection pigs are fitted with devices that accumulate information about the condition of pipe coatings. Transport pigs are mobilized to transport products through pipelines. The use of industrial pigging products provides numerous merits, such as lowered downtime, improved pipeline soundness, and reinforced operational productivity. These devices are universally installed in sectors such as oil and gas, water treatment, chemical production, and food manufacturing.Thorough Study of Pipeline Pigging

Pipeline pigging is an vital procedure used within the oil and gas realm to audit pipelines. This crucial operation incorporates sending purpose-built tools, called pigs, into the line. Pigs are crafted to advance through the length of the pipeline, performing various duties.

Numerous forms of pigs are on call, each built for a distinct purpose. Common employments of pipeline pigging entail monitoring for defects, cleansing, and applying coatings.

- Benefits of Pipeline Pigging

- Effects on Operational Efficiency

- Types of Pipeline Pigs

Proven Sanitation with Pigging Processes

Pigging mechanisms supply a proven answer for achieving sanitation inside channels. These processes incorporate dedicated instruments that pass through the ductwork, competently cleansing residue. The process is especially beneficial for sectors that demand rigorous spotlessness benchmarks. Pigging mechanisms furnish a low-expense and quick approach for sterilizing systems, reducing the likelihood of spoilage.

Opting for Pigging Tools for Particular Demands

Pigging hardware functions a key role in successful pipeline functioning. When electing pigging hardware, it is important to consider the specific criteria of your function. This requires evaluating details such as pipeline dimension, flow velocity, product category, and management standards.

Numerous pigging forms are present, each designed for distinct objectives. In particular, some pigs are intended for auditing, while others are deployed for extracting debris or distributing product quantities.

Moreover, pigging gear elements should be compatible with the conveyed material.

It is typically advisable to consult a technician in pigging systems to ascertain that you pick the most correct device for your distinct expectations.

Systematic Pipeline Cleansing - A Advantageous Approach

Channel purging solutions deliver a extensive variety of assets for fields focused on pipelines. By competently sanitizing and reviewing internal pipelines, pigging systems improve operational operations and lower maintenance outlays.

A primary merit of pigging systems is their aptitude to eliminate fouling such as dirt, debris, and decay products. This scheduled sanitation promotes frictionless pipeline stream and curtails costly downtime.

Moreover, pigging systems can be implemented to examine the condition of pipelines, finding foreseeable irregularities before they escalate into critical obstacles. This proactive strategy supports to enhance survival of pipelines and shrink overall maintenance expenditures.

Securing Hygiene in Pigging Functions

Piggy management operations significantly count on appropriate hygiene procedures to limit the passage of illness. Adhering to rigorous hygiene standards maintains a sound surroundings for pigs, thus generates augmented health outcomes and functionality.

Comprehensive cleaning and disinfection of premises is critical to reduce the level of harmful germs. Efficient droppings management additionally holds a vital part in supporting hygiene.

In pigging system addition, {workers