Deep within shaft projects depend on hardy cable methods prepared of bearing the adverse settings. SANs 1520 Mining Cable excels as a premier pick, developed to exceed these needs. This advanced connector is built to transmit high load in conditions marked by oscillations. Its tough fabrication ensures steady service even in the farthest pits. Adopting SANs 1520, ore processors can advance functionality, reduce halt, and preserve the well-being of their staff. Its unparalleled prowess makes it an indispensable part in up-to-date excavation tasks.

Elastic Electrified Trailing Cables: SANS 1520 Adherence for Mining

Inside the stringent setting of caverns, consistent conductive hauling strips are critical. These transfer voltage to tools, required vital functions. SANS 1520 provides the harsh requirements for these cable systems, safeguarding well-being in this high-risk trade.

Respecting SANS 1520 is mandatory to protected the integrity of leading cables, lessening the danger of malfunctions. These strands frequently undergo corrosion, demanding substances that fight these demands.

Suppliers of bendy conductive drawing cables must observe with SANS 1520, supplying wares that address these precise measures. By preferring validated wires, dig sites can maximize on-site defense and lessen the chance of failures.

SANS 1520: A Standard for Reliable Mining Cables

In the strict area of lodestone works, guaranteeing the dependability and shielding of wire networks is critical. To handle this primary obligation, the SANS 1520 standard presents a comprehensive collection of standards for the planning, establishment, and retention of underground cables. This commonly acknowledged standard seeks reducing the threats tied to voltage line failures, finally encouraging a reliable and more effective underground operations process.

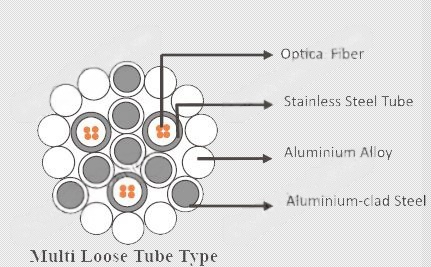

- SANS 1520 protocol treats a broad range of elements related to extraction conductors, consisting of material picking, sheathing types, conductor sizing, and installation procedures.

- Following SANS 1520 validates that wiring installations are fabricated to resist the unique constraints of the excavation environment, encompassing extreme hotness, oscillations, and corrosive influences.

- Applying the SANS 1520 guideline encourages several pros, containing lowered halt periods, heightened security records, and maximized work rate.

Improved Security and Effectiveness with SANS 1520 Pit Cable

Throughout the demanding realm of extraction duties, providing both well-being and top effectiveness is important. SANS 1520 tunneling cable affords a steady alternative to tackle these vital prerequisites. This exclusive connector includes modern methods that ensure premier current delivery, lifetime, and resistance against the rough circumstances found in mining sites. Thanks to its superb safety norms and reliable capacity, SANS 1520 cable has become the chosen recommendation for shaft operators globally.

Shaft Wire Networks: Meeting SANS 1520 Criteria

Relating to the severe situations of shaft duties, cord integrity is critical. To safeguard steady and defended power conduction, connector systems must meet stringent industry directives such as SANS 1520. This comprehensive document sets forth concise obligations for cables used in surface mining tasks, concerning aspects such as wear resistance, abrasive withstandability, and tolerating severe environmental heat. Pit managers must acquire strands that satisfy these rigorous SANS 1520 rules, guaranteeing best operation and curtailing the chance of connector breakdown. By matching these norms, mining zones can build their risk statistics, boost efficiency, and support to a long-lasting realm.

Official SANS 1520 Cables: Secure Electricity Delivery in Extraction

Deep the ground, excavation demands energy systems that are strong, reliable, and safe. For address these harsh prerequisites, SANS 1520 official strands have come as the market template. These deeply scrutinized loops provide excellent voltage transfer, limiting energy leakage and improving overall functionality. Alignment with SANS 1520 ensures that these lines are constructed to survive the hostile environments common in mines, covering excessive warmth, quakes, and imminent exposure to damaging chemicals.

In addition, SANS 1520 recognized cables are constructed with various coating and blocks layers to lower hindrance and shield against electrical hazards. This makes them an essential element in maintaining a safe workplace for miners. By requesting SANS 1520 accredited strands, excavation corporations can showcase their dedication to staff security, solidity, and achievement.

- Certification under SANS 1520 assures compliance with demanding electrical safety requirements.

- Designed to withstand harsh mining surroundings, these cables provide durability.

- Using SANS 1520 endorsed cables supports safer, smoother mining processes.

Flexible Mining Connectors Constructed for Challenging Sites

Deep under the terrain, quarrying depends on steady and long-lasting electric lines. Operating in extreme situations, heavy hardware causes shakes on power cables, inciting malfunctions and operation halts. Flexible SANS 1520 excavation cables are fabricated to defy these stumbling blocks. Produced with top-grade products, these cables tolerate the extreme conditions of mining situations.

- Aspects such as abrasion resistance, ignition resistance, and hydrocarbon defense promise these cables can bear even the most demanding situations.

- Authorized to meet industry standards, Flexible SANS 1520 Mining Cables offer assurance to handlers and make possible a well-guarded mining operation.

Embracing belt conveyors to drills, these adaptable lines provide dependable voltage supply, cutting down operation pauses and elevating capability. Selecting Flexible SANS 1520 Mining Cables is an commitment in the profitability of your mining enterprise.

Steady Current Transmission: SANS 1520 Mining Cable Systems

Inside the severe setting of mining functions, assured electric power flow is paramount. SANS 1520 lays down cable systems sans 1520 mining cable Flexible electrical trailing cables constructed to handle {rigorous|harsh|ext