dedicated corrugated container producer how do professional corrugated packaging manufacturers contribute to brand loyalty?

Examine the detailed process of corrugated carton development using this extensive handbook. We intend to analyze the primary procedures of changing plain sheets into robust containers that protect goods during transportation. Encompassing flute shaping, printing, and wrapping, we discover the subtleties of this important domain.

- Investigate the different sorts of corrugated parcels and their specialized roles.

- Investigate modern advancements in carton production.

- Examine the sustainability issues and renewable solutions.

Whether being an academic, specialist, or field admirer, this explanation conveys meaningful expertise on the fluctuating container manufacturing area.

Creating Innovations from Corrugated Sheets

Corrugated packaging board, generally overlooked as plain shipping medium, serves as a versatile crafting instrument. Its resilient traits permit the crafting of original constructs and layouts, incorporating handy bins to enchanting accents. By means of innovation, you can alter this normal component into anything unique.

Explore the boundless opportunities in corrugated fiberboard design through:

- Playing with diverse approaches including trimming, creasing, and layering

- Applying recycled supplies for a green technique

- Presenting your projects to stimulate others

As a result of its budget-friendly nature, availability, and multifunctionality, corrugated carton board appeals to designers of various ages and experience. Harness your inventive talent and facilitate your imagination to grow through this modest element.

The Harmony of Innovation and Artistry in Corrugated Packaging

Corrugated container crafting illustrates a mesmerizing combination of engineering and aesthetic appeal. It outperforms typical crafting; it prioritizes producing a defensive enclosure that shields goods throughout delivery while also making a significant impact on audiences.

An adept architect appreciates the refined aspects of corrugated pulpboard, adjusting its dimension, flute design, and layout to address distinct specifications of each asset.

- Additionally, design factors are vital.

- An expertly fashioned container is easily spotted on shelves, drawing attention from prospective customers.

- Basically, carton fabrication integrates shielding and attractiveness.

Meeting Demand: Scaling Your Corrugated Box Production

When commerce expands and sales soar, it's crucial to verify readiness for attending customer desires. Increasing carton output may unlock smooth workflows and solidify trustworthy standing.

To begin, review your operational capacity. Survey deployed equipment and crew to recognize likely slowdowns or areas for development. Later, evaluate means to improve production size. Consider investing in new machinery or upgrading your current assets to boost output.

Keep in mind, increasing quantity is secondary to optimizing overall workflow. Adopt streamlined manufacturing methods to limit leftovers and enhance material use. Refine operations, computerize monotonous duties, and focus on staff development to form a productive group.

In conclusion, cultivate dependable connections with providers to guarantee continuous resource delivery. Employing these approaches, you may productively grow packaging production and address climbing consumer requirements.

Innovation in Corrugation: The Future of Packaging

The packaging industry is constantly evolving, driven by the need for sustainable, efficient, and innovative solutions. Corrugated carton board, a dependable material for ages, undergoes resurgence fueled by pioneering developments. From strong structures to smart additions, corrugated pulpboard embraces forthcoming advancements. Companies research innovative approaches to improve container capabilities, using green components and operations. The upshot is a swell of inventive packaging projects modifying the industry backdrop.

These breakthroughs confront significant problems faced by firms, such as cutting waste and enhancing delivery networks. Consumers equally benefit from these innovations, with cartons that are safer and more functional. The horizon for corrugation is encouraging, packed with prospects for environmentally sound and efficient packaging frameworks.

Sustainable Corrugated Boxes: Eco-Friendly Choices

Corrugated containers represent a vital aspect of present-day supply networks. Commonly fabricated with fiber, these cases bear major effects on surroundings. Even so, heightened appreciation for eco-conscious strategies involves producing parcel goods. Luckily, fresh ideas are at hand to raise environmental responsibility of these cases.

A fundamental factor relates to adopting reclaimed stock. Using assembly or consumer remains, the demand for virgin components drops, preserving natural habitats and resources.

In addition, builders dedicate efforts to sustainable operational practices. These actions cover refining electricity use and lowering discard within fulfillment flows. Customers may contribute by selecting cartons verified as eco-friendly. Look for labels such as FSC or SFI, which guarantee responsible sourcing and manufacturing.

Via embracing these measures, we sustain cartons as vital market players while reducing ecological footprint.

Maintaining Superiority in Cardboard Packaging

Realizing top-tier output in container manufacturing involves strict quality supervision. Starting at resource procurement and finishing with final product review, every process calls for persistent care. Careful policies direct manufacturing phases to affirm every box meets ultimate specifications.

- Evaluating raw ingredients for errors, resilience, and homogeneity is important to circumventing subsequent troubles.

- Meeting accurate measures and tolerances in cutting and bending secures packages are mechanically stable and fit for application.

- Frequent analysis of printing ensures bold visuals and clear wording

- Adopting computerized evaluation tools boosts effectiveness and fidelity in assessment methods

By valuing quality oversight at each step, builders produce parcels that are resilient and visually striking. Such attention to detail appeases consumer desires and fortifies brand credibility.

Packaging Printing: Labeling and Effect

Box surface printing represents a fundamental factor in brand presence. As clients notice your merchandise, the container serves as an important medium for conveying a message. A thoughtfully developed image on a container can draw focus, represent brand character, and promote purchase behavior.

Furthermore, corrugated box printing offers a range of options to customize your packaging. Utilizing dazzling colors to novel symbols, it is feasible to communicate brand traits via packaging shape.

In the end, carton decoration is more than utility – it is a compelling device to amplify brand presence and connect with buyers.

From Base Components to Final Goods: The Corrugated Carton Process

The construction of packaging is a remarkable process changing basic ingredients into a vital delivery and containerization method. Everything starts with sourcing pulp, usually obtained from reclaimed materials. Then, pulp is formed into sheets of corrugated sheet, having a fluted core trapped between two flat liners.

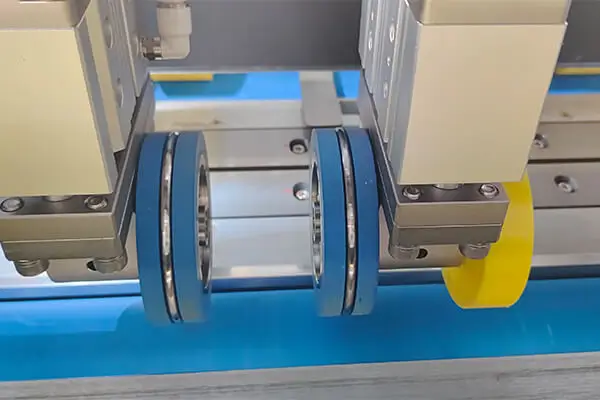

These sheets are meticulously cut according to precise specifications, then assembled using specialized machinery to create the desired box shape. Binders are essential for joining parts securely, guaranteeing a robust and lasting framework.

At last, packages face thorough evaluation routines to confirm physical soundness and adherence to market criteria.

Arising from unassuming starts, the parcel becomes a dynamic packaging marvel, suitable to preserve broad merchandise during transport.

International Packaging Sector: Developments and Potentials

The global corrugated box market is experiencing a period of growth. This flourishing business is energized by escalating corrugated box maker buyer expectations for packaging. Essential elements include advancement of online marketplace and desire for eco-conscious packaging